Marine frequency converters

A set of four power electronic converters developed and manufactured by the TWERD Department of Power Electronics with the total power of 1. 4 MW supplies four propulsors (main and main and manoeuvring) of the "Oceanograf" research catamaran built in the Gdynia shipyard "Nauta S.A." for the needs of the Institute of Oceanography at the University of Gdańsk.

These are the first Polish frequency converters installed in the main propulsion of the ship.

The set consists of four frequency converters with a power of 2 x 500kW and 2 x 200kW, which together with auxiliary devices have been placed in four separate cabinet units.

Block diagram of power circuit

Two 500 kW AC drives feed the main stern thrusters of the catamaran, while the two 200 kW power units feed the bow thruster propulsors.

Photos of cabinet units

The first picture was taken after the installation of the system on the ship, the remaining - in the company's headquarters.

Photos of stern and bow thrusters

Construction - cabinet installation

Each of the converters is installed in a ventilated cabinet with IP54 protection. The temperature inside the cabinet is controlled by a thermostat.

The cabinet doors are equipped with: main switch disconnector drive, safety switch, local control panel, cooling inlet grilles and handles. There are cooling exhaust fans on the roof.

Power and motor cables are inserted into the circuits through the EMC frames.

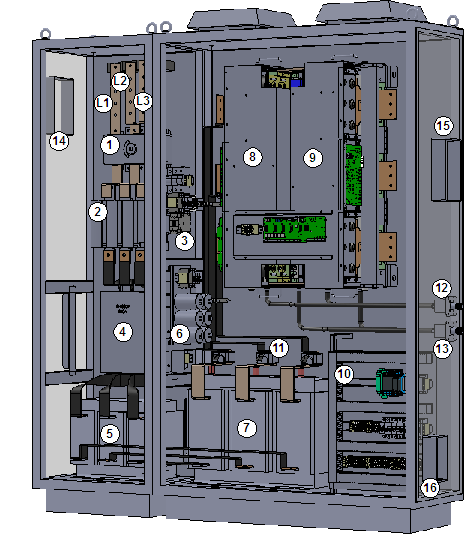

Arrangement of elements in the cabinet 500 kW

L1, L2, L3 - input buses

1 - disconnector

2 - main contactor K1

3 - pre-charge contactor K2

4 - RFI filter

5,6,7 - LCL filter

8 - AcR converter

9 - VSD converter

10 - assembly plate of the automation and protection system

11 - quick fuses F1, F2, F3

12,13 - cooling system connections

14 - EMC frame for input cables

15 - EMC frame for output (motor) cables

16 - EMC frame for control cables

Construction - power level

Each of the four systems consists of two three-phase two-level converters.

Simplified schematic diagram of one system

Between the ACR (AC / DC) and VSD (DC / AC) converters there is a DC (4) intermediate circuit. Via the LCL filter (1) the mains voltage is transferred to the network converter. The DC circuit is charged by a rectifier with a resistor limiter (6). Before applying voltage to the power circuit, one must give the voltage to the pre-charge system by switching on K2. After establishing the DC voltage, the control system switches on K1 and K2 is disconnected. The controller (9) manages the operation of the entire device, provides communication with the environment using I / O signals and a local panel (10).

Each of the 200kW systems is contained in one separate power block, while each of the 500kW systems consists of two blocks connected by DC buses. Directly on the casing there are precharge circuits of the capacitor bank, the controller of the active part of the AcR rectifier, the controller of the VSD part and the main controller. The main controller manages the operation of the entire device, provides communication with the environment using I / O signals and a local panel.

IGBT transistors connected in parallel are used as keys. They are placed on a liquid-cooled heat sink. DC-link capacitors are placed directly above the transistors.

The input stage was realized as a transistor active rectifier. This solution provides sinusoidal power consumption from the mains.

Current measurements are carried out using Hall sensors. Communication with the main controller is via a fiber optic link.

Cooperation with the Schottel control system

Cooperation with the PMS system

Each of the four drives individually communicates with the ship's power management system (PMS) developed by Praxis Automation Technology B.V. This system determines the power allocation for a given drive.

Technical data:

Total nominal power of the unit: 1.4 MW

Supply voltage: 400 V, 50 Hz

Nominal output current:

200 kW converters: 350 A

500 kW converters: 870 A

Cooling:

Power blocks: cooling liquid

Cabin: roof fans

Overall dimensions:

Four cabinet units, each measuring 1800 x 2090 x 570 mm.

Constructor: Jarosław Załęski